It is a system which should be used in all kinds of structures with high electrical voltage in terms of earthing, life and property safety. The purpose of the lightning rod grounding is to transmit the surge voltage caused by a lightning strike to the ground without damaging the operating means.

Lightning Conductor System is a system which is designed to ensure that the possible lightning falls on the catching ends and that the generated energy flows to the ground in a controlled manner with the down conductors and other connection parts and that the living things and the environment around are affected to a minimum.

Lightning rod systems are equipped with catch rods at the highest point and mounted at the top of the building. The earth conductor is connected to this rod and attached to the electrode in the ground. As a result, the lightning falling to the facilities is rendered harmless without damaging human life and being thrown to the ground in a way that does not cause a fire.

The resistance and inductance of the discharge path of all surge protection devices to the ground should be kept as small as possible. For this reason, the connection to the grounding electrode should be as straight as possible, without cornering and as short as possible.

The discharge of electrical charges between the cloud and the earth is called tadning. Because the air is not a good conductor in electrically charged clouds suspended in the air, it creates a voltage of about ten million Volts. At the moment these clouds are charged, the part of the storm cloud close to the ground is negatively loaded. Meanwhile, the place is loaded positively. As a result, the uploading process also occurs in the cloud as large as it occurs.

With the intensification of the storm, the separation of negative and positive charge in the clouds continues. As the storm intensifies, the insulating air between the cloud and the ground begins to become conductive, and the greater the potential difference between the cloud and the ground, the easier it is to pierce the air. By puncturing the air, the high voltage in the cloud is discharged to the ground. In these discharges, current flows between 2 bin and 200 thousand Amps.

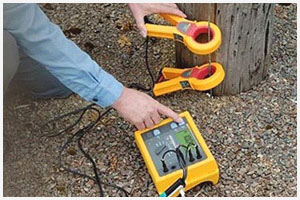

Grounding is the most serious measure that can be taken to protect against lightning and to prevent damage to the electric vehicles used. Lightning rod systems are the systems that transmit the sudden and high voltage that occurs at the time of lightning to the ground through the grounding line. The sudden high voltages generated by lightning strikes pass to the ground by following the predetermined path through the grounding system, thus preventing possible loss of life and property.

Actually, the working principle of the lightning rods is not to transmit the electric charge to the ground, but to prevent it from falling before the lightning strikes. Electricity tends to concentrate on objects that are pointed. Lightning occurs at the top of the building where lightning occurs, minus loads occur on the bottom of the rain clouds and pushes the minus loads in the lightning rod to the ground by means of a copper cable. As a result, the lightning load remains at the end of the lightning rod. These plus loads also spray upwards and neutralize minus loads in rain clouds. This prevents the lightning from falling off.

Occupational Health and Safety Law and Health and Safety Conditions in the Use of Work Equipment regulations in the tables attached (Annex 3 Maintenance, Repair and Periodic Inspection Considerations), lightning rods, Electrical Installation, Grounding Installation, Lightning Rod group. If no other time is specified in the relevant standards for lightning rods, periodic checks and examinations are required at least once a year.

Periodic inspections of the earthing of electrical installations according to the regulation, while periodic inspections of the lightning conductors must be carried out by electrical engineers, electrical technicians or high technicians.

For more information, please contact our expert team at our contact addresses and phone numbers.