The origins of the machine go back to the presence of the lever. Military engineers have used simple machine mechanisms, such as spinning wheels, ropes and pulleys, to create combat tools that were formerly used to encircle cities. The first industrial machines XVIII. century (1769 also steam machine). XIX. In the 19th century, many new types of machines were found and made available to the public (sewing machine at 1830. writing machine at 1873).

This century was indeed the period when machinery was widely used in industry. Machines can be classified as simple machines and compound machines. Simple machines that enable the development of energy using a very weak physical force contain a small number of components. These include lever, pulley, pulley, spinning wheel, jack.

However, the machines mentioned here and falling into the scope of periodic inspection of shipyards, factories, construction sites and so on. machines are often used in the workplace. The Machinery Safety Regulation regulates the basic safety conditions required for the design and production of machines that do not harm human health and safety and the goods, if they are duly established, regularly maintained and used for the intended purpose.

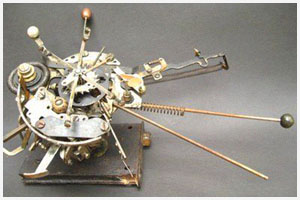

It is stated on the machines that should be evaluated within the scope of the Regulation In the Regulation, the machine is a group of parts which are equipped with a propulsion system other than human and animal power, which are assembled together for a specific application, and at least one of these parts are movable and do not have the necessary components for connection to an energy and motion source. capable of operating when installed in a transport vehicle or installed in a building

Mechanisms that are arranged and controlled to operate as a whole are mentioned.

Although trainings were given, due to the misuse of various machines and the lack of regular control, work accidents increased in working environments. Therefore, increasing the security measures to be taken has become a necessity. In accordance with the provisions of the Occupational Health and Safety Law No. 6331 in force, regular controls of many machines used in the enterprises are required. These checks must be made by mechanical engineers who are experts in their fields.

Inspection and test organizations provide services to check whether the machines in the low risk group are in compliance with the regulations criteria within the scope of Machinery Safety Regulation. These controls are carried out by expert engineers and reports are prepared as a result of the inspection. Before the inspection, the manufacturer companies have to keep the technical documents and product samples to be inspected ready for inspection to the market.

For more information, please contact our experts at our contact addresses and phone numbers.