Non-destructive testing (NDT in short) is a type of inspection without damaging the integrity of the material or part to be examined. The validity of this examination is based on the results of the destructive examinations.

Non-destructive testing methods are used to detect invisible discontinuities or discontinuities open to the surface of materials. It is used to measure the amount of material in a closed material, to detect paint thickness on metal surfaces, to detect the condition of the assembled parts, to radar systems.

In ultrasonic examination and industrial radiography, tests are performed by sending high energy rays with very small wavelengths such as ultrasonic sound waves, X or gamma rays to the region to be examined in general.

Errors or defects in materials are revealed with non-destructive testing methods. The amount of another material contained in a sealed material can be measured. In addition, the paint thickness on metal surfaces can be measured and the conditions of the assembled parts in materials where more than one part is mounted can be determined.

When performing non-destructive testing, during ultrasonic testing or industrial radiography, in general, ultrasonic sound waves or high energy rays of very small wavelengths such as X-rays or gamma rays are sent to the area to be examined.

Briefly, non-destructive material inspection is a form of inspection without damaging the examined materials and it is performed to obtain information about the dynamic and static structures of the material. The non-destructive testing method is used to detect, for example, cracks caused by abrasion, a gap in the internal structure and the like during the manufacture of materials or after a certain period of use. There is no need to take a sample of the materials during this inspection.

There are several methods of non-destructive testing. These methods are applied in different ways and with different physical principles. This is mostly shaped according to the type of material examined and the type of error sought. The methods applied are: eye examination, liquid impregnation examination, eddy currents examination, magnetic part examination, ultrasonic examination and radiographic (x-ray) examination.

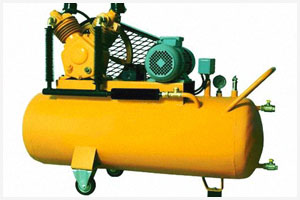

The periodic inspection and control of the compressors is a requirement stipulated by the Occupational Health and Safety Law No. 6331. According to the Regulation on Health and Safety Conditions of Work Equipment issued on the basis of this law, compressors accept compressors in the group of compressed air tanks. If no other period is foreseen in the relevant standards, periodic inspections of the compressors are required at least once a year.

If inspection and control operations are to be carried out by non-destructive testing methods, these checks should only be carried out by engineers, technicians or technicians trained in accordance with the TS EN 473 standard. "TS EN 473 Nondestructive testing, Non-destructive testing personnel qualification and certification, General rules" standard issued by the Turkish Standards Institute in 2010 year, but was canceled in 2013 "TS EN ISO 9712 Non-Destructive testing (NDT) personnel qualification" standard It has been published.