No matter how high the standard of design, application and testing of the air conditioning installation related to the clean room is, if the construction works in the clean room are not carried out in accordance with the clean room standards, it is very difficult to obtain the clean room cleaning class. It should not be forgotten that, for example, the contamination of the product or injector injected directly into the body in a hospital environment will definitely lead to death.

In addition to temperature and humidity, the control of parameters such as air flow directions, air pressure, and live and inanimate pollutants is essential for the clean room. In addition, steam, exhaust air, clean water and compressed air required by the production vehicles must be met.

Both live and non-living pollutants can contaminate the room. It is a little-known fact that the greatest living pollutant is human. Within a minute, nearly a thousand bacteria and fungi spread from our body. It must be removed from microorganisms, viruses and bacteria found in air and water.

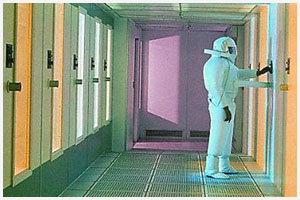

The presence of live contaminants such as microorganisms and bacteria is called sterile. The clean room is one hundred percent sterilization. In order to achieve this, it is necessary to bring the pollutants to minimum or even zero on any surface. These rooms are specially designed and kept under constant pressure and are called clean rooms.

The ISO 14644 Cleanroom standard is designed for clean rooms and controlled environments with these rooms. The basis of this standard is the 209E standard. TS 11605 standard is the standard translated by TSE and adapted to the conditions of our country. The ISO 14644 Cleanroom standard consists of four main topics: scope, recipes, classification and demonstration of conformity.

Control procedures for monitoring and documenting the performance of production processes are called validation. The purpose of this process is to keep every step of the production stages under control. Validation operations can be made for vehicles that affect production or used in production. In this case, the specifications, installation, measurements and performance of the vehicles used are checked. Or validation procedures can be done for each product produced.

There should be clean rooms in hospitals, pharmaceuticals, laboratories and food sectors which affect the human health in particular and the producers are responsible and the compatibility of these clean rooms with standards should be tested by neutral organizations.

Particle measurement, Differential pressure measurement, Temperature and humidity measurement, Recovery test, Calculation of air flow rate and number of air changes, Hepa filter tightness tests must be performed by qualified personnel without error.

Death incidents as a result of design or application failure in Clean Rooms designed to obtain a sterile product

It is obvious that it will emerge. The purpose of the tests and controls carried out during both the design and implementation phase is to ensure that the design and application is made of very high quality and to prevent possible errors.

It should not be overlooked that with the implementation of similar control methods in HVAC Projects of comfort and other industrial facilities, the material and moral losses of both the employer, the designer and the implementers will be prevented to a great extent and the quality will increase.

For more information, you can reach our expert team from our contact addresses and phone numbers and you can get answers to all your questions.